5 Important Details to Include in a Metal Finishing Quote

Want to minimize back and forth during the metal finishing quoting process? Be sure to provide as much information as possible when requesting a quote.

This advice applies to any customer seeking metal finishing services, but it’s especially important for machine shops requesting these services on behalf of their customers. The longer the supply chain, the more opportunities there are for communication challenges to delay a project.

We highly recommend that machine shops communicate with customers about the details of a project before bringing a metal finisher into the process. Otherwise, they risk submitting a quote with insufficient information and having to convey the metal finisher’s questions back to their customer before the quote can even be finalized.

Acting as the middleman isn’t a good use of a shop’s time or energy, and the “game of telephone” can create too much back and forth between metal finisher and end customer. We’ve seen quotes that should have been relatively straightforward delayed by up to a week due to communication challenges.

If you’re unsure about what kind of information you should ask your customers to include, Global Metal Finishing is happy to share our recommendations. Here’s a closer look at 5 important details to include in a metal finishing quote.

5 Important Details to Include in a Metal Finishing Quote

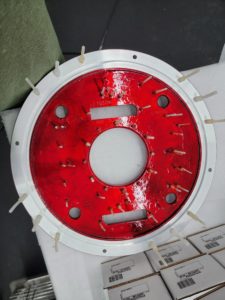

1. Masking directions

Parts with holes present challenges during metal finishing, so it’s important to include detailed masking directions in the quote. Two areas to pay attention to are hole size and threads:

- Hole size. The smaller the hole on a part, the bigger the challenge it presents. Extremely small holes often end up trapping miniscule amounts of liquid such as water, acid, or cutting fluid during the machining process.

When liquid becomes trapped inside the hole of an aluminum part, the inside of the hole may not get properly anodized. Small holes are also at risk of trapping acid during the finishing process, which may later bleed out and damage the part.

If holes are 5mm or smaller, we recommend plugging them during the metal finishing process. Calling out small holes that can be plugged on your drawings will improve the quality of your parts and reduce unnecessary back and forth communication.

- Hole threads. Threads in holes—especially small holes—present tolerancing challenges because the extra millimeters of thickness resulting from anodizing can throw a part out of tolerance. It’s important to factor this extra thickness into the part design.

There’s also the possibility that anodizing won’t reach the bottom of a hole. In most cases, only the first 3-4 threads will be anodized. It’s important for shops to keep this limitation in mind when discussing parts with customers. Be sure to include finishing requests for hole threads in the metal finishing quote.

2. Surface finish instructions

When it comes to surface profiles, there is much more than meets the eye. That’s why metal finishers use profilometers to provide a detailed analysis of the profile of a part’s surface.

Profilometers measure the profile and surface finish of the part. To achieve the maximum benefit from our profilometer analysis, it’s best to provide us with as much information as possible about surface finish requirements. At a minimum, indicate the desired surface finish using an Ra number.

3. Critical tolerance data

The metal finishing process can add up to 2 mm of additional thickness to the surface of a part. That means if a part has tolerances of less than 2 mm, then the metal finishing process could compromise those tolerances. It’s important for machine shops to consider this information when machining a part that will ultimately require metal finishing.

It’s also important to include detailed tolerance specifications in a metal finishing quote and to note whether the dimensions are pre- or post-anodizing dimensions.

4. Step file with PDF

It’s a best practice to provide a step file along with a PDF when requesting metal finishing services. The step file allows metal finishers to visualize the part in 3D so that they can see dimensions such as volume and surface area.

When we receive step files and PDFs up front, we can turn quotes around quickly and with an exceptional degree of accuracy.

5. Color details

For decades Global Metal Finishing has led the metal finishing industry in color innovation and execution. We can finish your part in any color except white. Discussing the color of the finished part is one of the areas we spend the most time on with our customers, so anything machine shops can do to streamline communication with the end customer is recommended.

When requesting a custom color, provide a sample in the quote so that we can match the color exactly. For the fastest turnaround, we recommend choosing from our list of standard colors to finish a part. Using standard colors expedites the finishing process substantially.

At Global Metal Finishing, it’s our goal to get customers their parts as quickly as possible. No matter how much information you include in your quote, we’ll work with you to deliver the part you need. But if you want to expedite the process, be sure to include as many details as possible. Request a quote to work with us!